XLPE (Cross linked Polyethylene) Medium Voltage (MV) Cables have proven to be very superior in terms of electrical performance allowing for improved power loading compared to MV Paper insulated Lead Cables (PILC), however, PILC are still very common in many coastal areas and wet lands in South Africa. The PILC product has been preferred for years due to its special features of lead sheathing which allows for improved radial water blocking protection against moisture and water ingress and improving the life of a cable extensively – some cables have been in use for over 40 years in these networks.

Though PILC cables have proven to be resilient there are many challenges for its continued use. PILC cables are made by the use of paper impregnated with oil as its insulation and lead extrusion under sheathing. PILC Cables may pose negative environmental issues related to oil contamination when there is a cable fault at high temperatures or on cable disposal when burning. The lead or lead alloy in the PILC has to be disposed in controlled environments which may pose challenges to many users of this product. Many countries across the world have discontinued the production of Paper Insulated Cables due to their negative environmental impact and South Africa is still one of the few countries, if not the only one in the world that is still manufacturing PILC cables for new installations because of its demand in the coastal and wet lands, as well as in few mining applications.

Aberdare Cables through its research and development initiatives has managed to find an innovative solution that improves the mechanical performance of the XLPE cables to allow for their use in the coastal areas and wet lands in South Africa. This has been successful through engagements of the users of the PILC Cables to understand their justification for the reluctance to move to the MV XLPE cables which have already proved to have better electrical performance in terms of current rating for the same cable size.

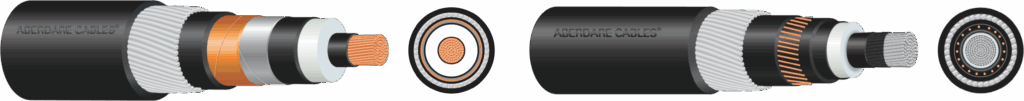

This new innovative solution of MV XLPE Cables which is now being produced locally by Aberdare Cables at its Port Elizabeth Stanford Road Factory, consists of a radial water blocking feature making use of Aluminium Laminate technology, addressing the draw backs to change from PILC to more environmentally friendly MV XLPE cables and allowing for improved life in MV XLPE Cables. This product is available for offer in Africa and globally as well.

The new innovative solutions is already covered in the local standards SANS 1339 of 2020. SANS 1339 is a compulsory standard in South Africa covering cables with voltages rated from 6.6kV to 33kV (MV Cables). This standard specifies longitudinal and radial water blocking for MV Cables when required by the user of the cable. Longitudinal water blocking is the most commonly deployed water blocking method as applied by many cable manufacturers in the local market, mainly because it is relatively easy to implement. Longitudinal water blocking alone, however, may not be enough to offer lasting water blocking capabilities of a cable in some environments, especially in areas that have high water levels in ground. Offering radial water blocking then becomes key to cables to ensure enhanced water blocking capability, of MV XLPE cables at design and manufacturing level. Radial water blocked cables are not very common in South Africa for MV Cables; they are common for high voltage (HV) cables for 44kV-132kV rated cables (making use of CSA (Corrugated Seamless Aluminium))

Prepared by:

Donemore Torerwa; Electrical Engineer; MEng, BSc (hon)

GM: Product Development and Applications

Aberdare Cables Pty Ltd